AUTHOR : SOFI PARK

DATE : 18/12/2023

Introduction

In the realm of automotive safety, one crucial component often overlooked is the precision-stamped polymer (PSP) used in wiper blades. The choice of PSP can significantly impact the performance and durability of wiper blades, making it a critical consideration for both manufacturers and consumers. In this article, we delve into the concept of high-risk PSP for wiper blades in India, exploring its implications, market dynamics, and ways to make informed choices.

Understanding High Risk PSP

Precision-Stamped Polymer, or PSP, is a vital element in the production of wiper blades. Its role goes beyond merely being a material; it affects the overall quality, longevity and effectiveness of the wiper blade. High Risk PSP refers to instances where the choice of polymer may pose challenges, leading to suboptimal performance or safety concerns.

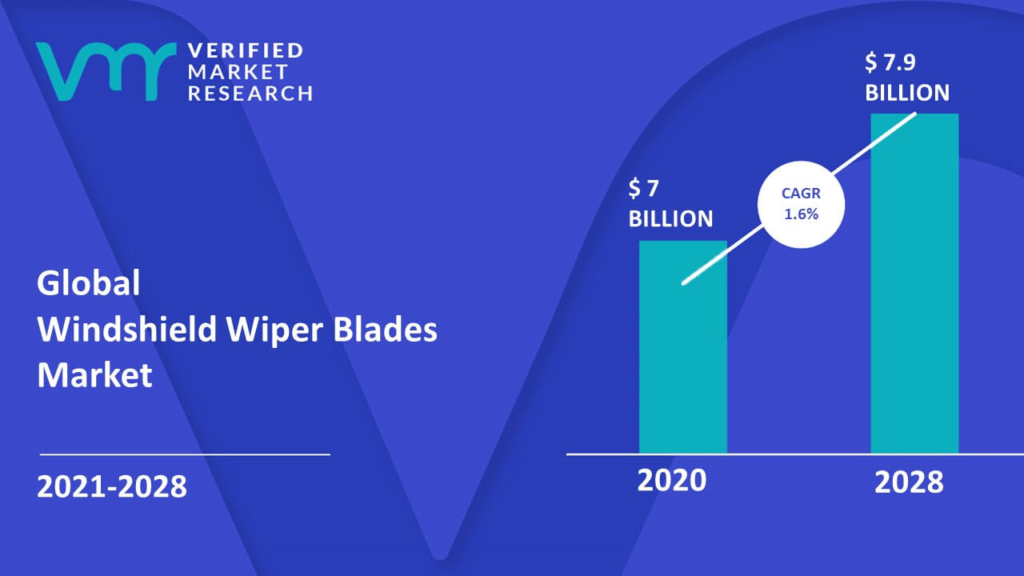

Market Overview of Wiper Blades in India

Before delving into the intricacies of High Risk PSP, let’s take a moment to understand the current landscape of the wiper blades market in India. With a burgeoning automotive industry, the demand for reliable and efficient wiper blades has been on the rise. Key players in the industry are continually striving to meet these demands while navigating evolving consumer preferences.

Identifying High Risk Factors in PSP

High Risk PSP factors can vary, encompassing environmental conditions, material quality, and manufacturing processes. In a country like India, where diverse climates prevail, the challenges faced by wiper blades are amplified. Manufacturers must be vigilant in identifying and mitigating these risks to ensure optimal performance and customer satisfaction.

Impact of Low-Quality PSP on Wiper Blade Performance

Choosing a subpar PSP can have dire consequences for wiper blade performance. Reduced visibility during adverse weather conditions poses safety risks for drivers. Moreover, low-quality PSP may result in frequent replacements, leading to increased costs for both manufacturers and consumers.

Regulatory Measures for Wiper Blades in India

Recognizing the significance of wiper blades in vehicular safety[1], regulatory bodies have established standards and certifications. Manufacturers must adhere to these guidelines, ensuring the quality and safety of their products. Compliance with these measures is a fundamental step in minimizing the risk associated with PSP.

Choosing the Right PSP for Wiper Blades

The process of selecting the right PSP involves careful consideration of various factors[2]. Manufacturers and consumers alike should prioritize thorough research and testing to ascertain the reliability and performance of the chosen polymer. This proactive approach significantly reduces the likelihood of encountering High Risk PSP scenarios.

Consumer Awareness and Education

In the pursuit of ensuring quality wiper blades, consumer awareness[3] plays a pivotal role. Educating consumers about the significance of PSP, how to identify high-quality materials, and the impact on overall safety empowers them to make informed decisions.

Industry Innovations in PSP for Wiper Blades

Innovation is a driving force in any industry. Technological[4] advancements in materials and manufacturing processes contribute to the continuous improvement of wiper blades. Sustainable and eco-friendly options are gaining traction, aligning with the global shift towards environmentally conscious practices.

Balancing Cost and Quality in PSP Selection

While prioritizing quality is paramount, balancing cost considerations is equally crucial. Manufacturers can explore cost-effective[5] strategies without compromising on the quality of the chosen PSP. Investing in premium materials may entail initial costs but often proves cost-effective in the long run.

Expert Recommendations for PSP in Wiper Blades

Industry experts emphasize the importance of collaboration and knowledge-sharing. Insights from those deeply entrenched in the field can guide manufacturers and consumers towards best practices in selecting PSP. These recommendations serve as valuable guidelines for enhancing overall product quality.

Future Trends in Wiper Blades PSP

Looking ahead, the wiper blades industry is poised for continued evolution. Emerging technologies and materials are on the horizon, promising improved performance and durability. Manufacturers and consumers should stay abreast of these developments to make strategic decisions in PSP selection.

Conclusion

the choice of Precision-Stamped Polymer for wiper blades is a critical factor influencing their performance. Understanding the nuances of High Risk PSP, market dynamics, regulatory measures, and innovations equips manufacturers and consumers with the knowledge needed to make informed choices. By prioritizing quality over shortcuts, the industry can enhance safety standards and provide superior products.

FAQs

- What is High Risk PSP for wiper blades?

- High Risk PSP refers to instances where the choice of Precision-Stamped Polymer may pose challenges, leading to suboptimal performance or safety concerns in wiper blades.

- How does low-quality PSP impact wiper blade performance?

- Low-quality PSP can result in reduced visibility, safety risks, and frequent replacements, increasing costs for both manufacturers and consumers.

- What regulatory measures exist for wiper blades in India?

- Regulatory bodies have established standards and certifications that manufacturers must adhere to, ensuring the quality and safety of wiper blades.

- How can consumers identify high-quality PSP?

- Consumers can educate themselves about the significance of PSP, conduct thorough research, and look for products that meet regulatory standards.

- What are the future trends in wiper blades PSP?

- Future trends include emerging technologies and materials, promising improved performance and durability in wiper blades.