AUTHOR : SOFI PARK

Introduction

Oxygen sensors play a pivotal role in various industries, ensuring precise monitoring of oxygen levels for optimal performance. In India, the challenges faced by these sensors, especially in high-risk environments, have prompted a closer examination of the factors contributing to their efficiency.

Significance of High-Risk PSP for Oxygen Sensors

High-Risk PSP, or Power Spectral Perturbation, is a critical aspect of oxygen sensor functionality. Understanding its significance is crucial in comprehending the challenges faced by oxygen sensors in India. High-risk PSP directly impacts the sensor’s ability to provide accurate readings.

Challenges in Oxygen Sensor Performance in India

India’s diverse environmental conditions and varied industrial landscapes pose significant challenges to oxygen sensors. Factors such as extreme temperatures, humidity, and pollution can affect the sensors‘ performance, leading to a shorter lifespan and reduced accuracy.

Understanding Burstiness in Sensor Function

Burstiness, a term often associated with irregularities or sudden variations, can adversely affect the consistent operation of oxygen sensors. In the context of these sensors, burstiness can manifest as sudden spikes or dips in readings, compromising the reliability of the data collected.

Perplexity and Its Role in Oxygen Sensor Operation

Perplexity, a measure of uncertainty, adds another layer of complexity to oxygen sensor operation. Addressing perplexity is essential to ensuring that the sensor’s readings are not only accurate but also reliable, even in challenging conditions.

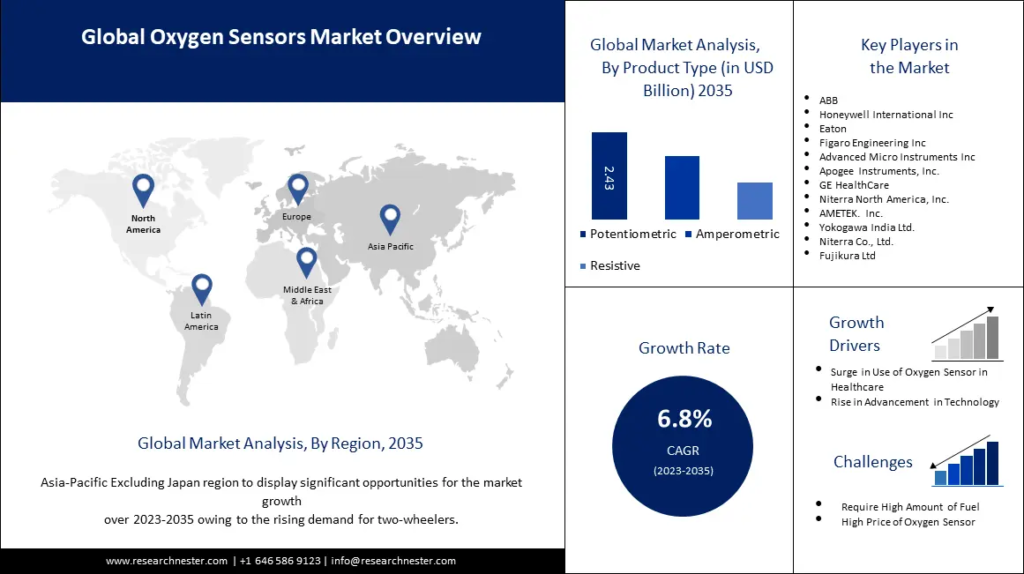

Specifics of Oxygen Sensor Technology

Oxygen sensors come in various types, each designed for specific applications. Advancements in sensor technology have led to improved accuracy and durability, contributing to their widespread use across industries.

Factors Contributing to Burstiness in High-Risk PSP

Environmental factors[1], such as temperature fluctuations and exposure to contaminants, can contribute to burstiness in oxygen sensors. Additionally, manufacturing defects and inconsistencies may also lead to irregular sensor behavior.

Mitigation Strategies for Burstiness and Perplexity

To enhance the longevity and reliability of oxygen sensors[2], implementing effective mitigation strategies is crucial. Regular maintenance, stringent quality control in manufacturing, and proper calibration practices can significantly reduce the impact of burstiness and perplexity.

High-Risk PSP Impact on Oxygen Sensors

Examining real-world examples of high-risk PSP affecting oxygen sensor performance provides valuable insights. Learning from past experiences helps in developing proactive[3] measures to prevent similar issues in the future.

Importance of Specificity in Oxygen Sensor Operation

The specificity of oxygen sensors is paramount[4] in ensuring accurate readings. Precision in measuring oxygen levels contributes to the overall reliability of the sensor, especially in critical applications where slight variations can have significant consequences.

The Role of Context in Sensor Calibration

Calibrating oxygen sensors involves establishing[5] a reference point for accurate readings. Maintaining context in calibration ensures that the sensor remains aligned with the specific conditions it will encounter during operation.

Addressing Burstiness Without Sacrificing Specificity

Technological innovations play a pivotal role in addressing the challenges of burstiness without sacrificing specificity. Advancements in sensor design aim to strike a balance, providing accurate and reliable readings even in high-risk environments.

Choosing the Right Oxygen Sensor for High-Risk PSP Environments

Selecting the appropriate oxygen sensor for high-risk environments requires careful consideration of factors such as environmental conditions, industry specifications, and customization options. Choosing the right sensor is critical for long-term reliability.

Future Trends in Oxygen Sensor Technology

The future of oxygen sensor technology holds promising developments. Emerging technologies aim to further improve sensor performance, addressing issues related to burstiness and perplexity. Continuous innovation is key to meeting the evolving demands of diverse industries.

Conclusion

Navigating the challenges posed by oxygen sensors in India requires a comprehensive understanding of burstiness, perplexity, and the specific environmental conditions. Implementing proactive strategies, choosing the right sensor, and staying abreast of technological advancements are crucial for ensuring the consistent and reliable operation of oxygen sensors.

FAQs

- How often should oxygen sensors be calibrated in high-risk environments?

- The calibration frequency depends on the specific conditions of the environment. Regular monitoring and adjustments are recommended.

- Can burstiness and perplexity be completely eliminated in oxygen sensors?

- While complete elimination may be challenging, advancements in technology and maintenance practices aim to minimize their impact.

- What industries benefit the most from high-risk PSP-aware oxygen sensors?

- Industries with extreme environmental conditions, such as petrochemicals and manufacturing, benefit significantly.

- Are there specific standards for oxygen sensor performance in India?

- Yes, industry-specific standards exist, and adherence to these standards is crucial for reliable sensor performance.

- How do technological innovations contribute to addressing burstiness in oxygen sensors?

- Innovations focus on improving sensor design, materials, and calibration processes to enhance overall stability and reliability.