AUTHOR : SOFI PARK

DATE : 19/12/2023

Introduction

Fuel pumps are the lifelines of any vehicle, ensuring the efficient delivery of fuel to the engine. However, the often-overlooked component, the Pressure Control Solenoid (PSP), plays a pivotal role in this process. In the context of India, the use of high-risk PSPs poses significant challenges to the automotive industry. This article delves into the intricacies of these challenges, examining the factors that categorize PSPs as high-risk, their consequences, and the measures needed to address this pressing issue.

Understanding High-Risk PSPs

Pressure Control Solenoids (PSPs) are electromechanical devices that regulate fuel pressure within the pump. Their role is critical in maintaining the optimal functioning of the engine. However, not all PSPs are created equal. Some are deemed high-risk due to factors such as substandard materials and inadequate quality control during manufacturing. High-Risk PSP For Fuel Pumps In India.

The consequences of using high-risk PSPs can be severe. From decreased fuel efficiency to complete pump failure, the impact extends to both vehicle performance and the owner’s pocket. It’s imperative to understand the intricacies of PSPs to grasp the severity of the challenges faced in the Indian automotive landscape.

Current Scenario in India

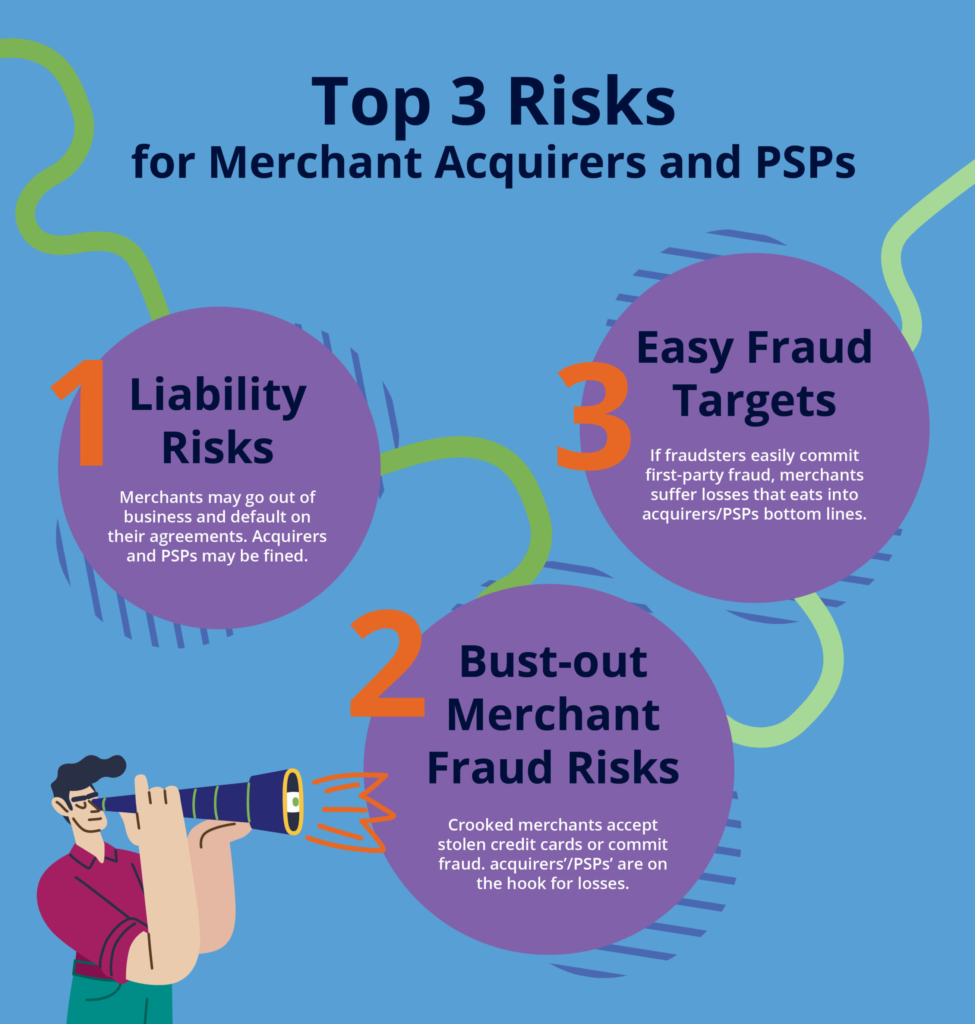

India’s automotive industry is one of the fastest-growing in the world, but it grapples with challenges related to the quality of PSPs. The sheer volume of vehicles on Indian roads amplifies the consequences of using subpar components. While regulatory measures are in place, gaps persist, leaving room for the proliferation of high-risk PSPs.

Challenges faced by the industry include a lack of standardized testing procedures, limited awareness among consumers, and the presence of unscrupulous manufacturers. These challenges collectively contribute to the prevalence of PSPs that fall short of quality standards.

Common Types of High-Risk PSPs

Several factors contribute to categorizing a PSP as high risk. One prevalent issue is the use of substandard materials. Manufacturers cutting corners to reduce costs often compromise on the quality of materials, leading to a domino effect of problems within the fuel pump system.

Another common challenge is the absence of stringent quality control processes during manufacturing. Inadequate testing and oversight result in PSPs with inherent defects reaching the market, posing a serious risk[1] to vehicles and their owners.

The impact on fuel pump[2] performance is multifaceted. High-risk PSPs not only compromise fuel efficiency but also accelerate wear and tear on the entire pump system. This, in turn, leads to increased maintenance costs for vehicle owners.

Importance of Quality PSPs

Investing in high-quality PSPs is not merely an option; it’s a strategic necessity. Quality PSPs[3] contribute to enhanced fuel efficiency, ensuring that vehicles consume fuel optimally. Moreover, they play a crucial role in prolonging the lifespan of fuel pumps, reducing the frequency of repairs and replacements.

Reduced maintenance costs are an additional benefit of using high-quality PSPs. While the initial investment might be higher, the long-term savings far outweigh the short-term costs. Vehicle owners stand to benefit from fewer breakdowns, lower repair bills, and increased overall reliability.

Choosing the Right PSP

Selecting the right PSP involves a combination of research, awareness, and adherence to industry standards. Fuel pump manufacturers[4] and vehicle owners alike must prioritize choosing reputable PSP manufacturers with a proven track record of producing high-quality components.

Research-based decision-making is paramount. Identifying manufacturers with positive customer reviews, certifications, and a commitment to quality control practices ensures that the chosen PSP meets or exceeds industry standards. Collaborating with reputable suppliers is a proactive step in safeguarding the efficiency of fuel pumps. High-Risk PSP for Fuel Pumps[5] in India.

Conclusion

The challenges posed by high-risk PSPs for fuel pumps in India are multifaceted and impactful. The consequences extend beyond individual vehicle owners to the automotive industry as a whole. Recognizing the urgency of addressing this issue is the first step toward a more reliable and efficient future for Indian vehicles.

FAQs

- Why are high-risk PSPs a significant concern in India?

High-risk PSPs pose a significant concern in India due to their potential to compromise fuel efficiency, increase maintenance costs, and lead to pump failure. - How can vehicle owners identify high-quality PSPs?

Vehicle owners can identify high-quality PSPs by researching reputable manufacturers, checking for certifications, and seeking recommendations from trusted sources. - What role do regulatory measures play in addressing high-risk PSPs?

Regulatory measures aim to set standards for PSP quality; however, despite these efforts, gaps in enforcement and awareness still exist. As a result, this necessitates a collective effort from industry stakeholders to address these challenges and ensure better compliance moving forward. - Are there any initiatives to increase awareness about PSP quality in India?

While initiatives exist, there is a need for more comprehensive campaigns to educate consumers, manufacturers, and industry professionals about the importance of PSP quality. - How can the automotive industry work together to mitigate the risks associated with high-risk PSPs? Collaboration between manufacturers, suppliers, and regulatory bodies is essential. Establishing and adhering to industry standards, sharing best practices, and raising awareness collectively contribute to mitigating risks associated with high-risk PSPs.