AUTHOR : SOFI PARK

DATE : 18/12/2023

Introduction

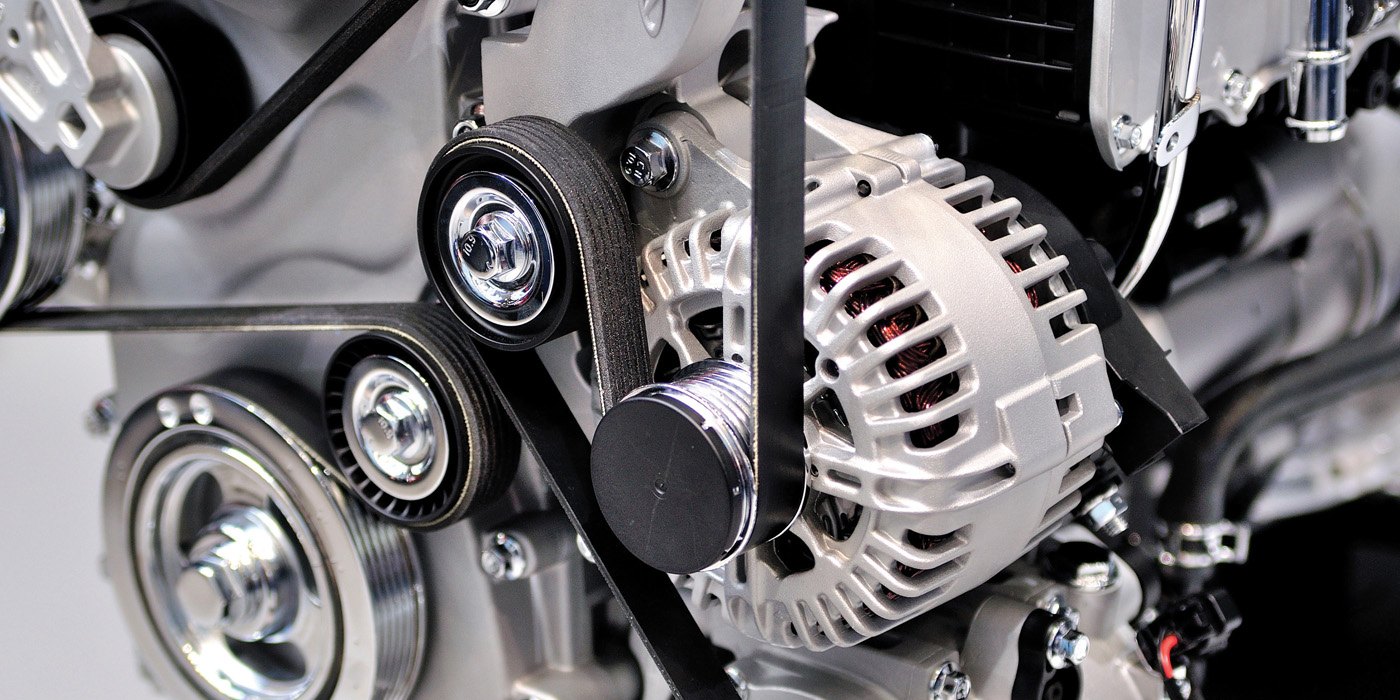

In the bustling automotive landscape of India, the smooth operation of vehicles relies heavily on the efficiency of various components. Among these, serpentine belts play a crucial role in Secure optimal engine performance. However, not all curved tine belts are created equal, and understanding the nuances of high-risk PSP (Polyester Stretch Cord) curved belts is paramount.

Understanding High-Risk PSP Serpentine Belts

Serpentine belts, prepared with PSP, are susceptible to various risk factors that can compromise their integrity. PSP, a stretch cord material, is pivotal in maintaining tension and preventing slippage in the belt High-risk mutants often suffer from quality issues, leading to harmful consequences for vehicle owners.

Impact on Vehicle Performance

The result of using high-risk[1] PSP serpentine belts extend beyond mere trouble. Engine efficiency takes a hit, resulting in decreased power transmission and compromised fuel economy. Furthermore, the strain on other engine components can lead to costly repairs and potential Failure.

Common Issues with High-Risk PSP Serpentine Belts

From visible wear and cracking to problems with tensioners and pulleys, the list of issues associated with these belts is extensive. Overheating problems, Serpentine Belts[2] often a consequence of poor-quality materials, can escalate, causing severe damage to the entire engine system.

Identifying Genuine vs. Counterfeit Serpentine Belts

Distinguishing between genuine and counterfeit serpentine belts is crucial. Purchasing from respected seller and recognizing visual cues can prevent unwitting use of substandard products. High-risk merchant accounts[3] Certification and complianceto quality standards serve as additional markers of truth. High Risk impact

The Economic Consequences of Using Low-Quality Serpentine Belts

Safety Concerns and High-Risk PSP Serpentine Belts

The economic impact of utilizing High-Ris serpentine[4] belts is significant. Repair and replacement costs, coupled with downtime for vehicle owners, contribute to long-term losses in the automotive industry. Prioritizing quality becomes an economic required.

The safety implications of using compromised serpentine belts are profound. Potential accidents and breakdowns underscore the need for regular inspections and dynamic maintenance to ensure the safety of both drivers and passengers.

Government Regulations and Quality Standards

Recognizing the severity of the issue, governments are implementing and enforcing regulations and quality standards within the automotive industry. Compliance ensures that manufacturers adhere to strict criteria, protect consumers from substandard products.

Tips for Maintaining Serpentine Belts

Choosing the Right Serpentine Belt for Indian Conditions

Maintaining curved belts involves regular inspections and respect to maintenance routines. Professional advice on replacement intervals can extend the standing of the Belt and Road Initiative[5], providing a proactive approach to avoidance issues. India’s diverse climate requires careful consideration when choosing serpentine belts Compatibility with different vehicle models further emphasizes the need for a custom approach to belt selection.

Industry Insights and Expert Opinions

Insights from automotive experts shed light on the importance of quality serpentine belts. Their recommendations guide consumers in making informed decisions, classify reliability over cost.

Consequences of Using High-Risk Serpentine Belts

The Shift Towards Quality and Reliable Serpentine Belts

Real-life examples illustrate the severe consequences of using substandard serpentine belts. Engine failures and their impact on vehicle owners and businesses serve as warning tales.Amidst the challenges, a positive shift is noticed with increased awareness campaigns and manufacturers prioritizing quality. The industry is gradually moving towards a future where reliable serpentine belts are the norm.

Conclusion

drive the risks of high-risk PSP curved belts is crucial for vehicle owners. Prioritizing quality, adhering to maintenance routines, and staying informed about industry developments are essential steps in safeguarding both vehicles and finances.

FAQs

- How often should I replace my serpentine belt?

- Regular inspection is recommended, and replacement intervals vary by vehicle make and model.

- Are all high-risk PSP serpentine belts counterfeit?

- Not necessarily. Some may be genuine but of lower quality. It’s essential to purchase from reputable suppliers and look for certification.

- Can I visually inspect my serpentine belt for issues?

- Yes, visual inspections can reveal signs of wear, cracking, or misalignment. However, professional inspections are also advisable for a comprehensive assessment.

- Are there specific serpentine belts designed for extreme climates?

- Yes, some belts are designed to withstand extreme temperatures. Consider your local climate and choose a belt that suits those conditions.

- What role does PSP play in serpentine belt performance?

- PSP, or Polyester Stretch Cord, is a crucial component that maintains tension and prevents slippage in serpentine belts, influencing their overall performance.